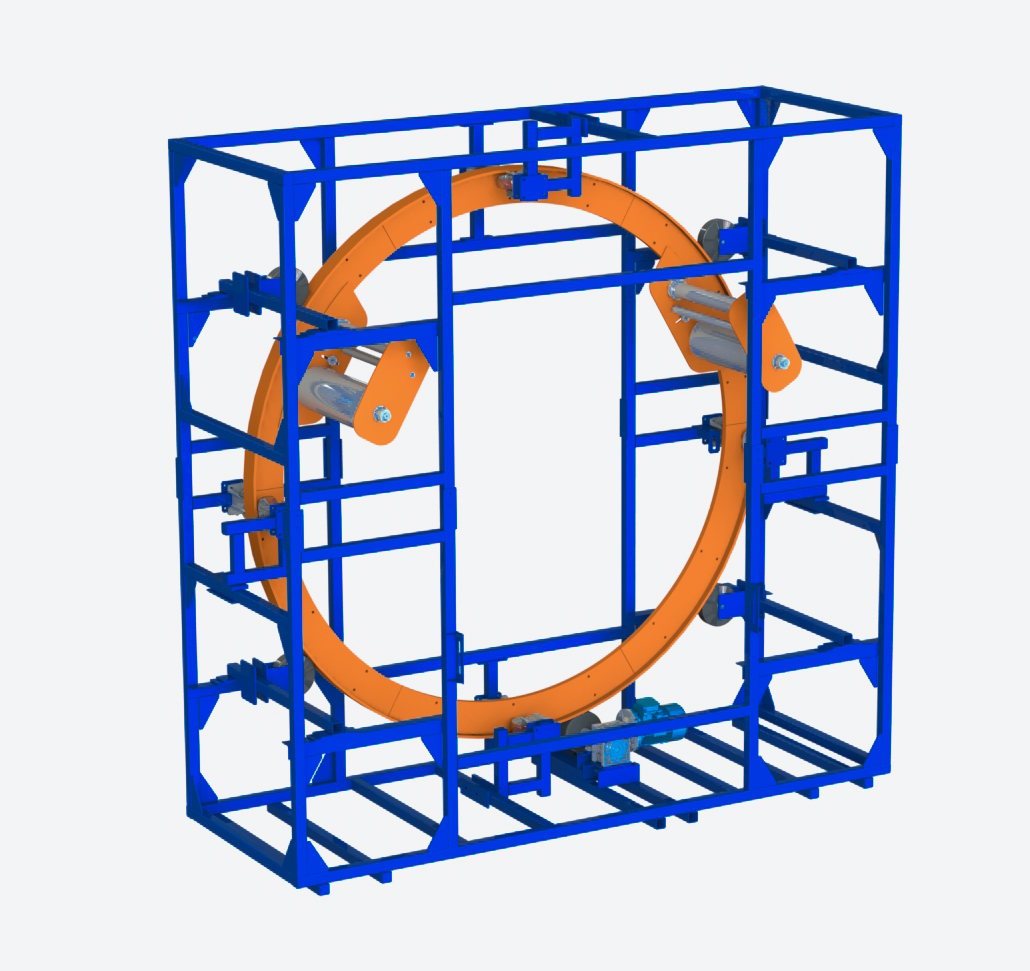

UG. 3.11 Turn over unit

Turn over unit is designed to turn the finished roof sandwich panels, which are then stacked into a stack with the ribs facing each other. This reduces the height of the finished pile of shipped products and prevent damage to the edges of the panels during further transportation.

Specification

- Length, mm: 13900

- Width, mm.: 3680

- Height, mm.: 1930

- Weight, kg.: 4300

- Mains voltage, V - Hz : 380 В – 50 Гц

- Power consumption, kW: 6

View other modules and sections of sandwich panel continuous laminating production lines

Sandwich panel production lines

«Basic»

Provides the possibility of further modernization and guaranteed quality of output product

Warranty service for 12 months from the date of launching the line.

Installation and commissioning

Post-warranty service and technical support

Post-warranty service and technical support