The use of modern methods of panel preparation and bonding, taking into account the experience of Russian materials, allows for savings of up to 20% in adhesive compared to imported counterparts.

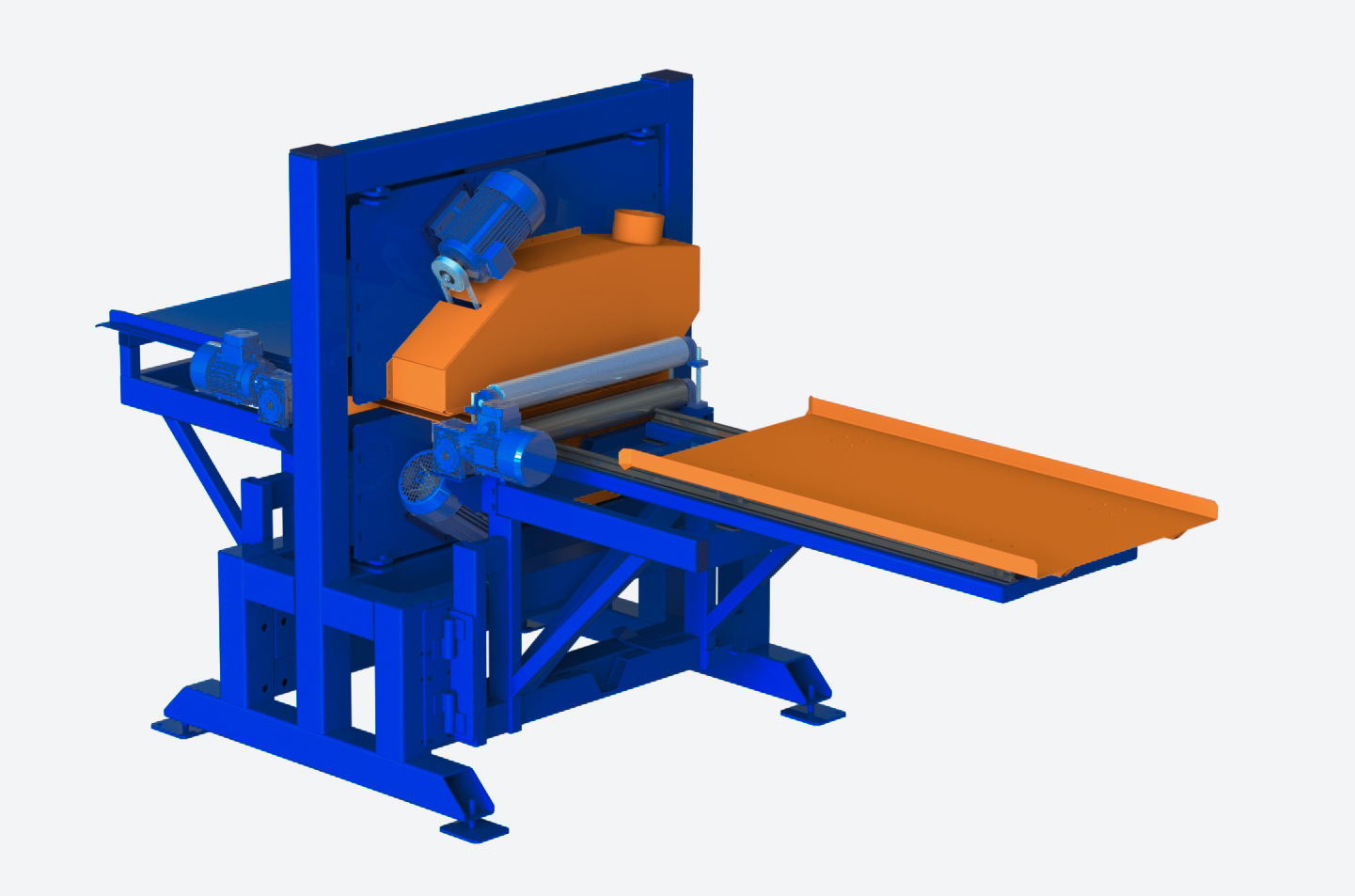

Automated lines for

continuous production

of sandwich panels

Russian manufacturer of sandwich panel continuous laminating production lines

The possibility to install line on facilities from 1 000 sq.m. and more

High line output: up to 8 m³/min.

Personal: from 8 labours

-20%

30 m

With "Automated sheet metal stitching", there is no need to use idle metal when changing to a different type or RAL of sheet metal

up to 30 m of sheet metal savings per coil

6 mon.

The payback period is from 6 months, subject to 100% capacity utilization.

24/7

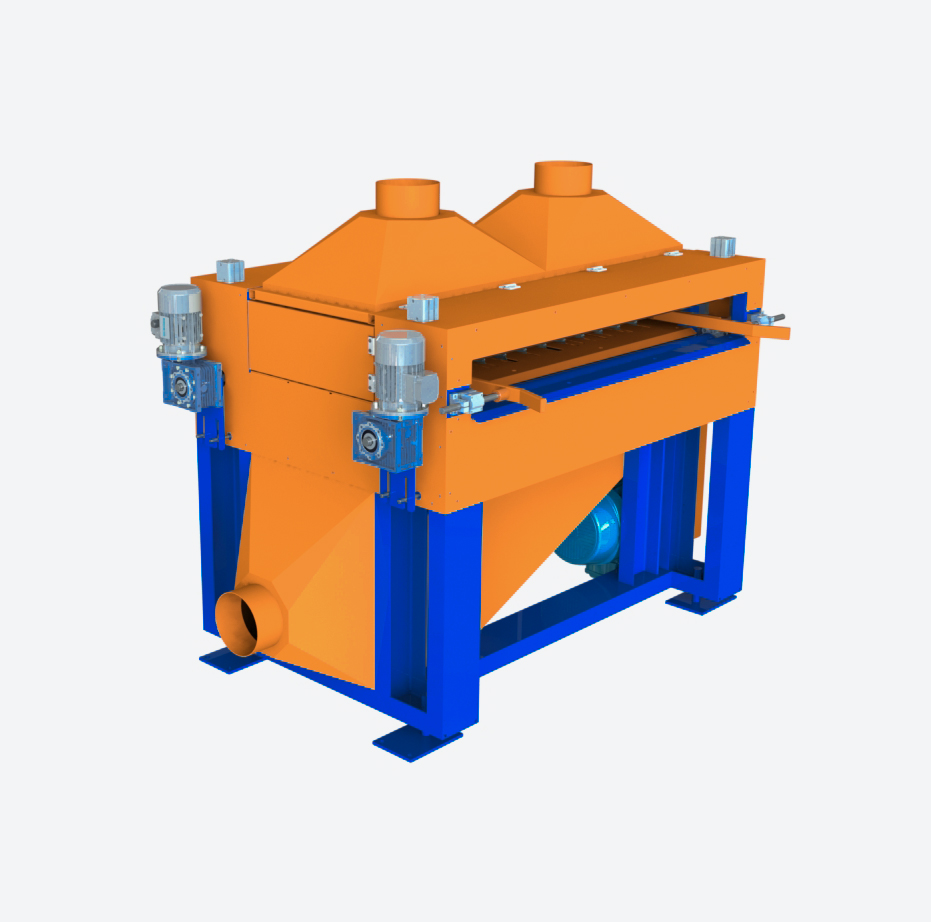

Automated control of the state of the system, online accounting of products, adjustment of technological factors affecting the quality of products.

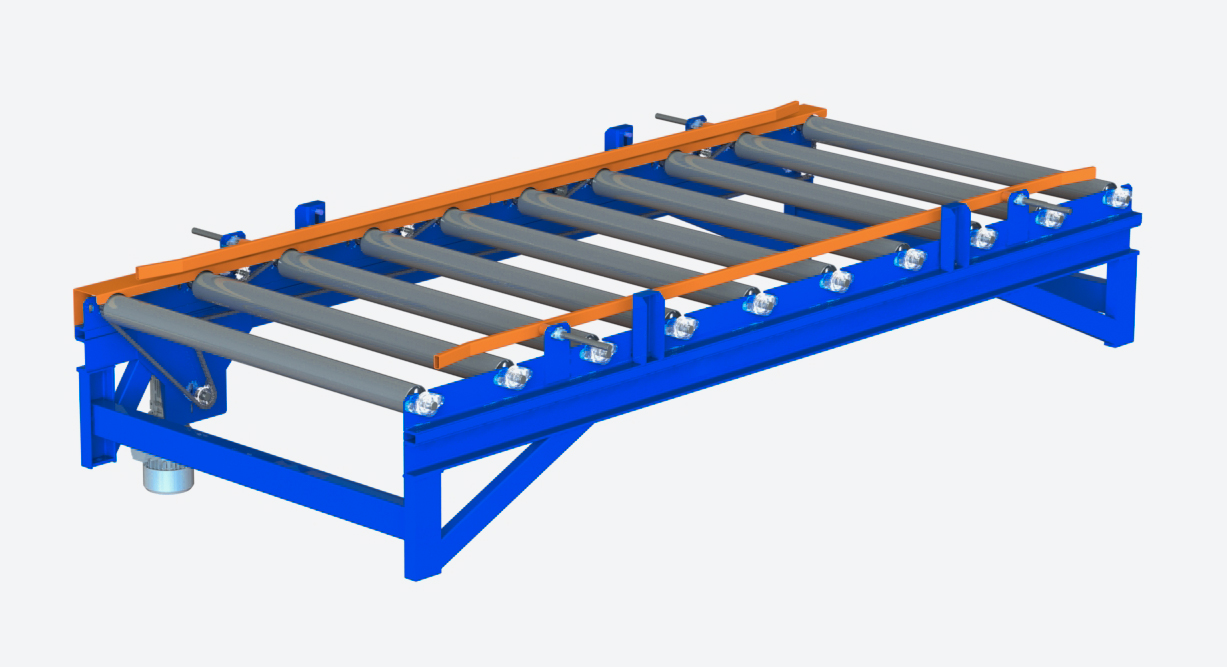

Modular line system for the continuous production of sandwich panel continuous laminating production lines

Specifications

- Output: up to 4 000 m²/shift

- Personal: from 8 labours

- The possibility to install line on facilities from 1 000 sq.m. and more.

- 3 types of equipment control system to choose from: Simens, Mitsubishi, Kinko

- 5 off profiling types

- 3 Joint types + customised lock design according to customer's drawings

- Length of Caterpillar type iM-Press only 6-12 m, allows you to save speed and production volume without loss of quality

- Ability to integrate into current lines of other manufactures

Specifications

Specifications of sandwich panel continuous laminating production lines

«Optimal»

Provides a high degree of automation and a wide range of output product

«Basic»

Provides the possibility of further modernization and guaranteed quality of output product

Output products comply in acc. to GOST standard 32603-2021

This means you can participate in any public tenders in Russia and sell your products to large companies

- Panel thickness: 50 to 350 mm

- Length of panels: 2.5 to 13 m (optionaly longer)

- Panel width: 1190 mm (wall panels) 1000 mm (roof)

- Core: mineral wool, lamellas, EPS and PIR blocks

- Density mineral wool: 95 -115 kg/m³

Joint types customised lock design according to customer's drawings

Z-lock

Significantly increases the speed of installation, increases the fire resistance of the structure, ensures minimum heat loss with proper sealing of joints.

Roof lock

The classic design of the roof joint, ensures a reliable sealing of the joints.

Secret Fix

Increases thermal insulation with aesthetics, inferior to the Z-Lock in terms of speed of installation.

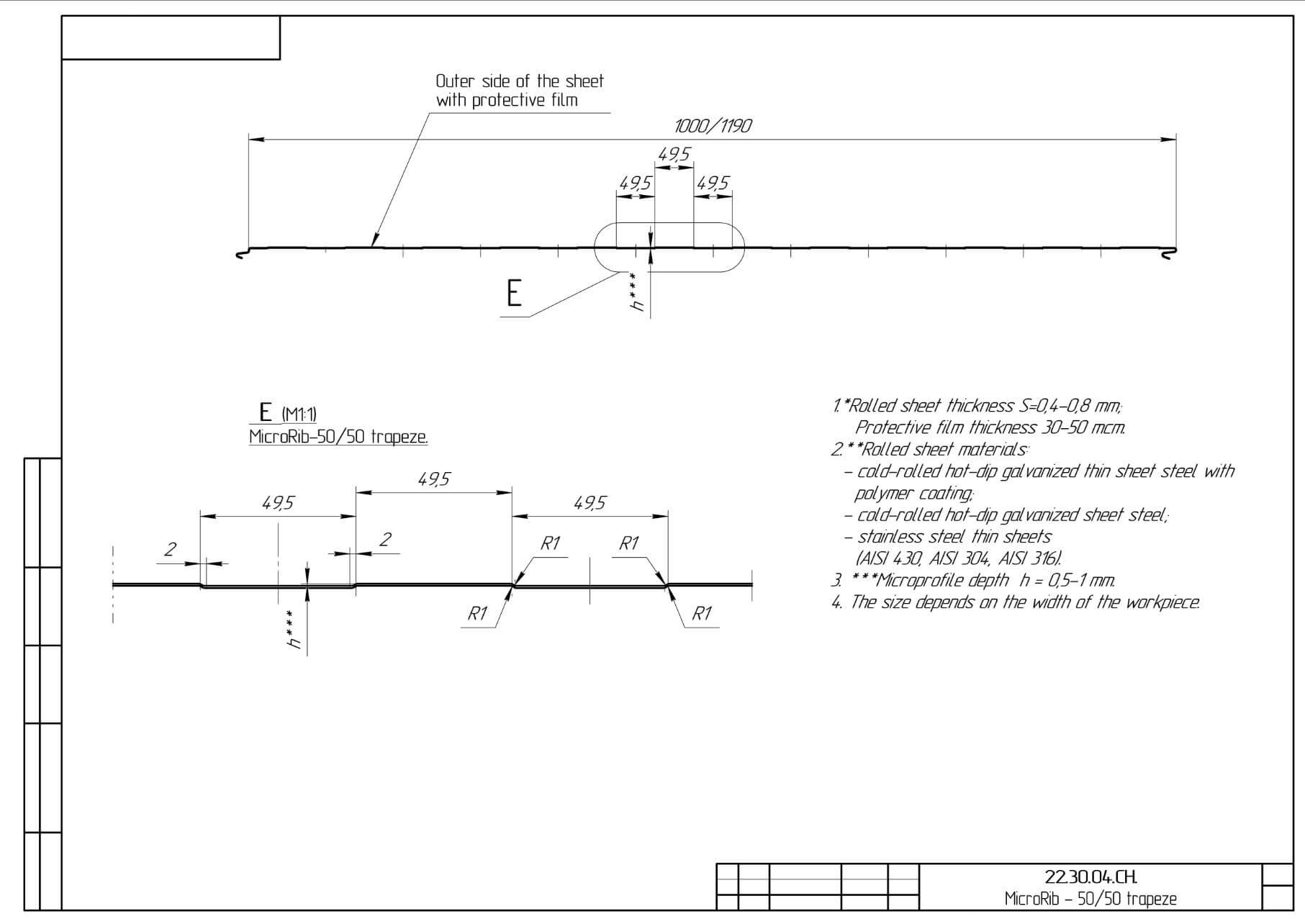

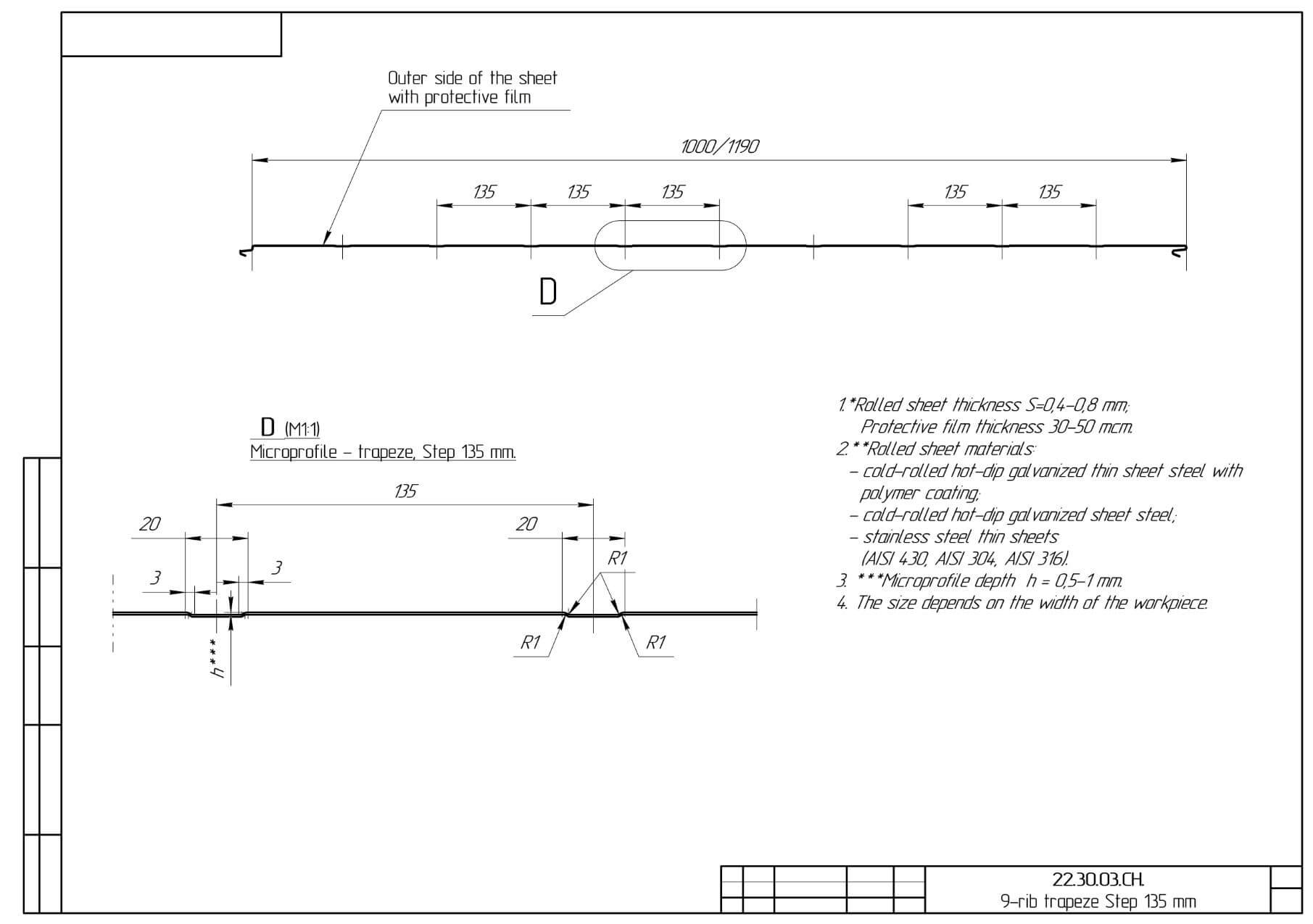

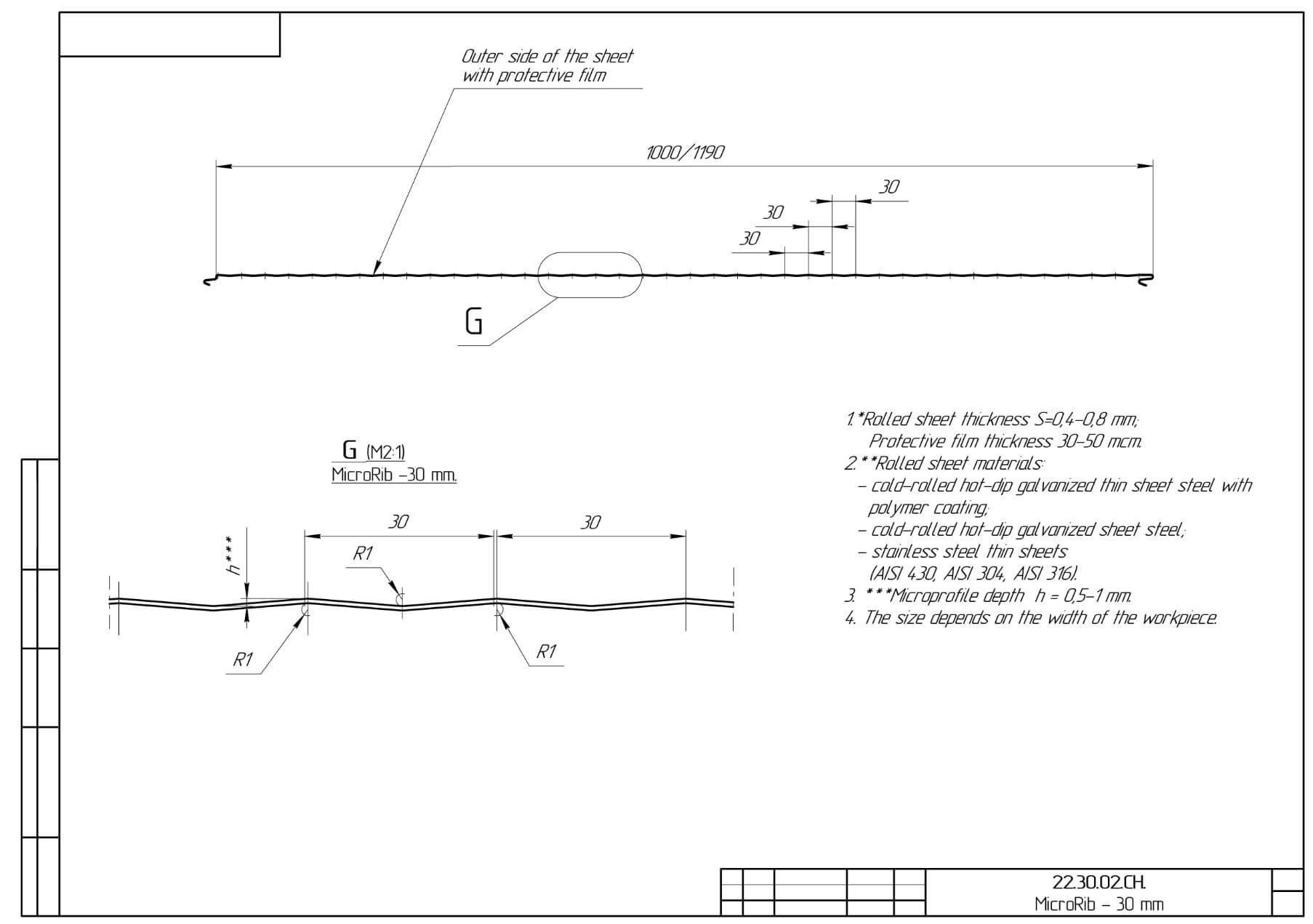

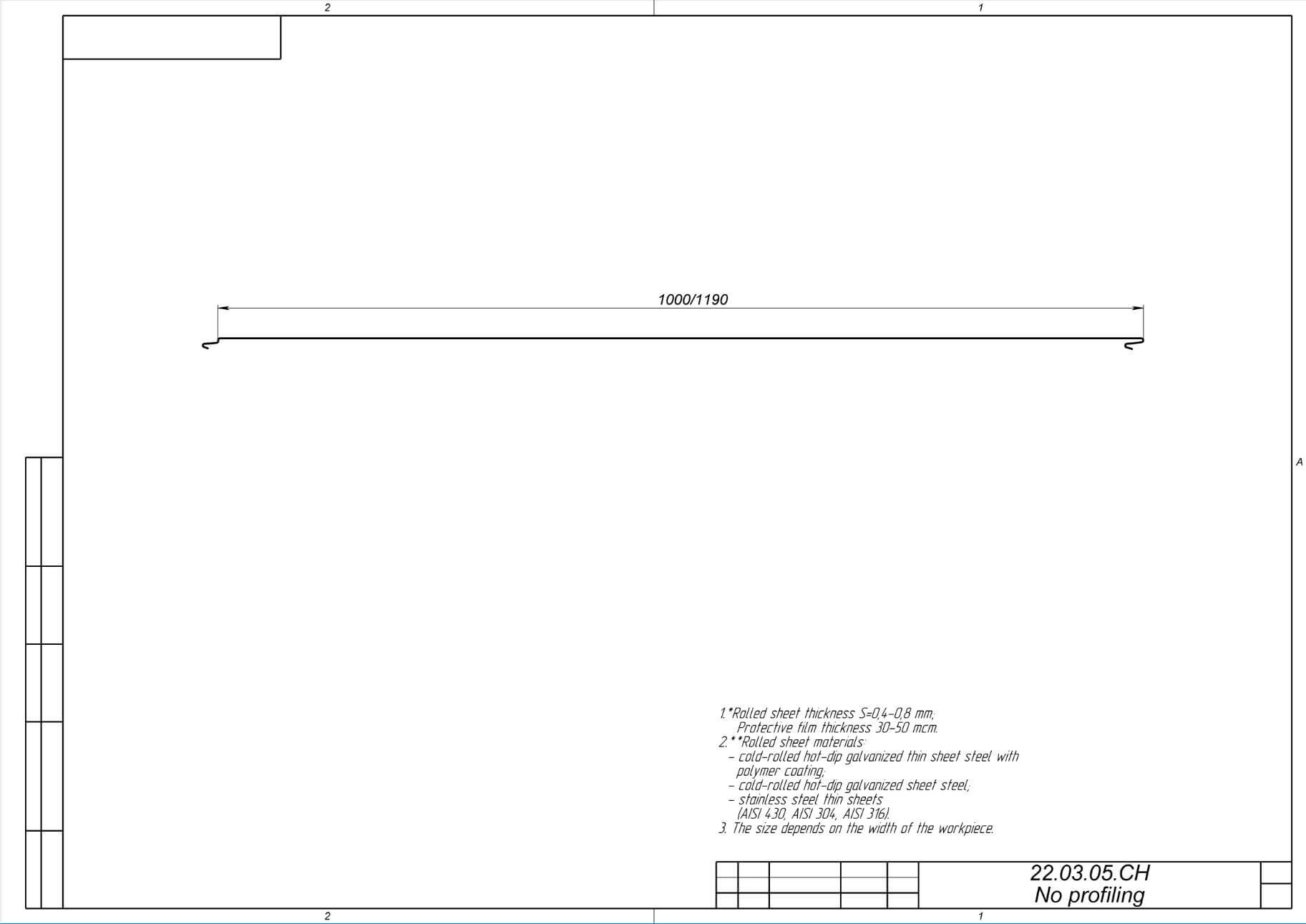

5 off profiling types

Payment

Standard conditions

Standard conditions payment of the main stage after signing the contract. Payment is made according to individual conditions, which are prescribed in the contract. As a rule, this is:

- 60% of the cost of the supplied equipment is an advance payment

- 30% when ready for shipment

- 10% after the NDT and commissioning of the supplied equipment

Warranty service for 12 months from the date of launching the line.

Installation and commissioning

Post-warranty service and technical support

Customer staff training

Control of all technical and technological

processes of production

Computer production management platform

Stores and analyzes data on technical processes and events in real time

Collects and aggregates data from all stages of production

Connects the causes of the malfunction and the operating time

Integrates robotic systems and technologies

Combines network infrastructure: wired and wireless

Controls any parameter on a mobile device

Excludes unplanned downtime and non-conditioning

Prevents emergencies and increases the level of safety