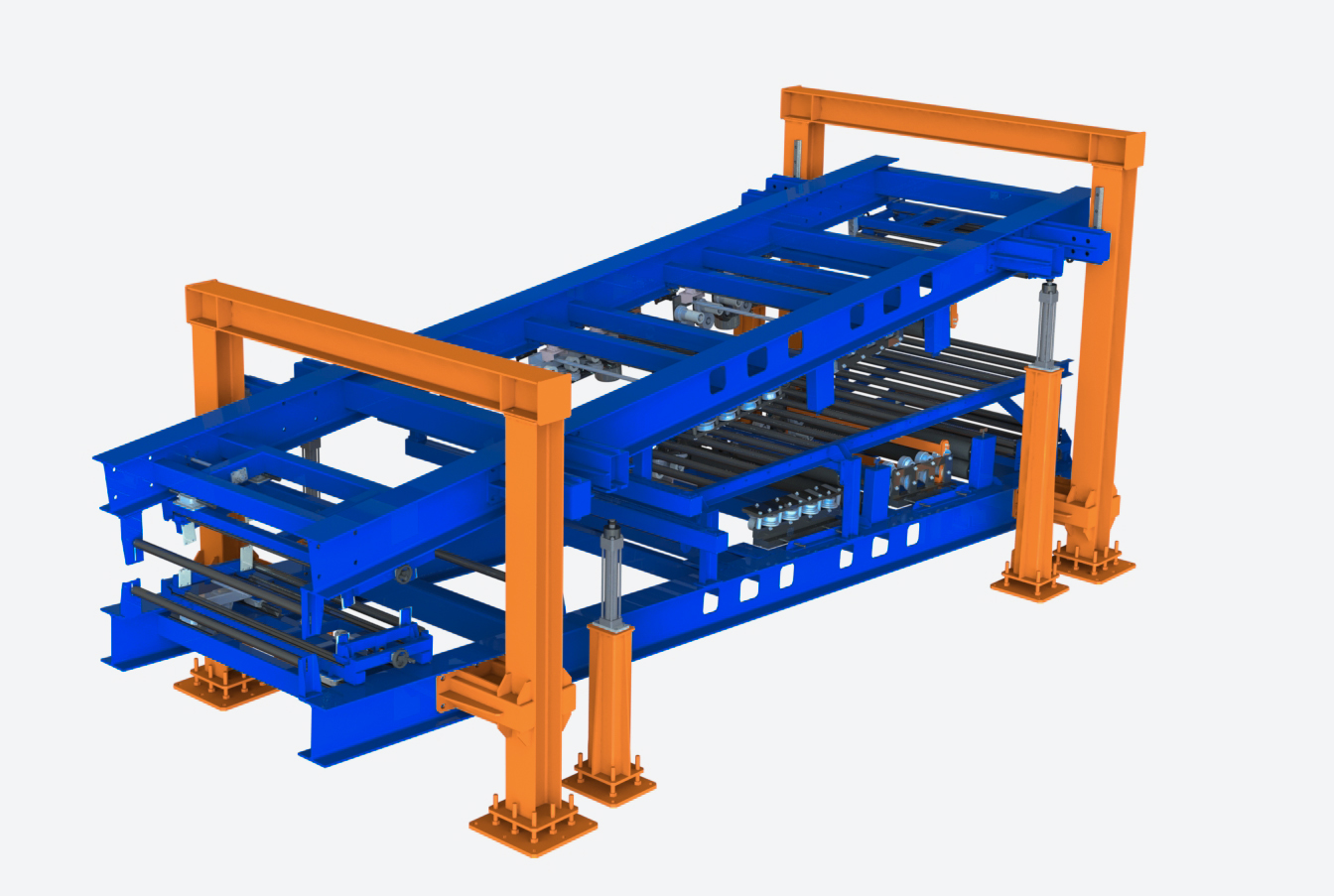

US. 2.1 Laminator

Laminator forms sandwich panel locks, applies adhesive, brings together the cladding and the mineral wool mat for subsequent feeding into the press.

Specification

- Length, mm: 7115

- Width, mm.: 2930

- Height, mm.: 2900

- Weight, kg.: 9960

- Mains voltage, V - Hz : 220/380В-50Гц

- Power consumption, kW: 10

View other modules and sections of sandwich panel continuous laminating production lines

Sandwich panel production lines

«Basic»

Provides the possibility of further modernization and guaranteed quality of output product

Warranty service for 12 months from the date of launching the line.

Installation and commissioning

Post-warranty service and technical support

Post-warranty service and technical support