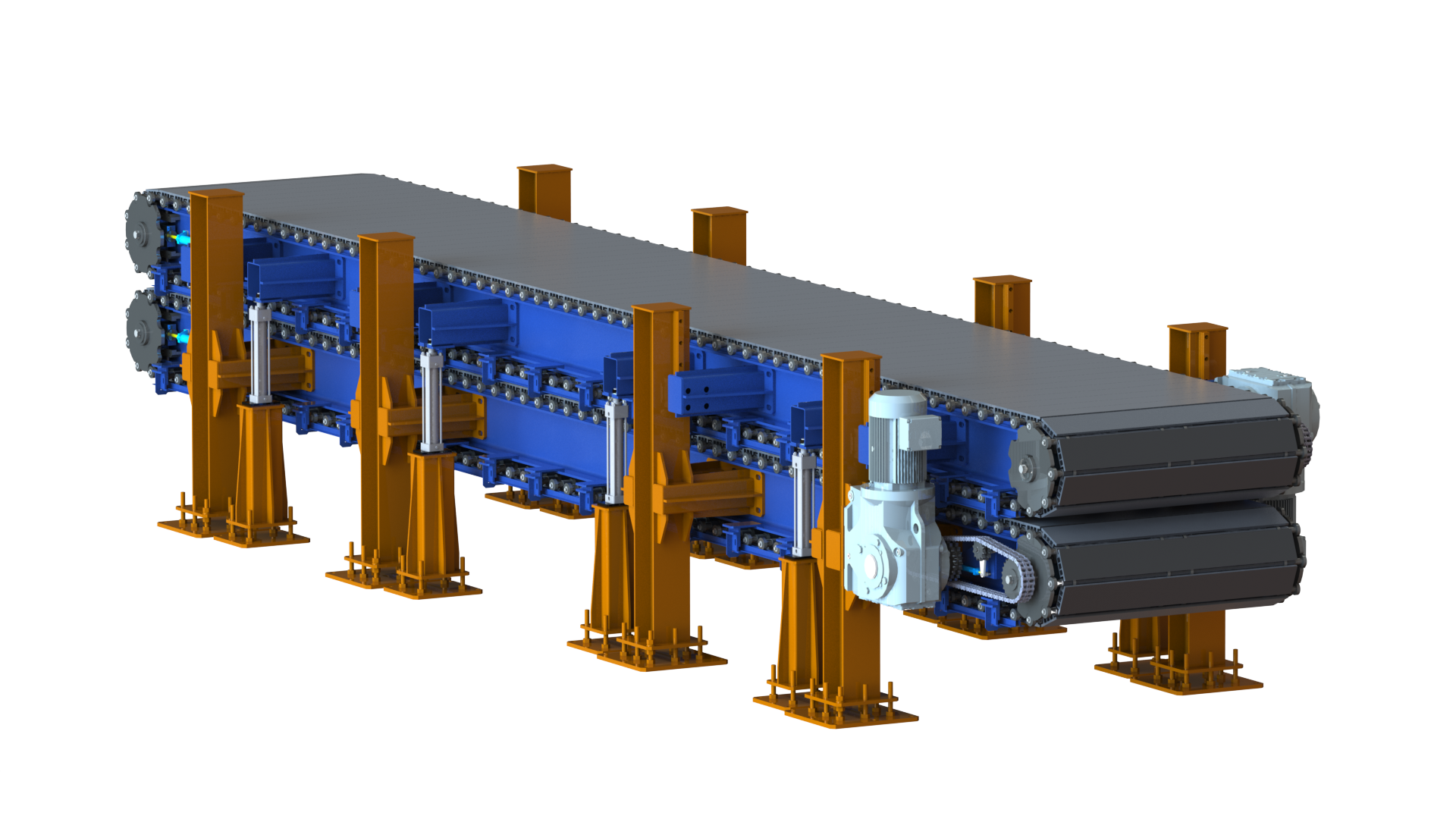

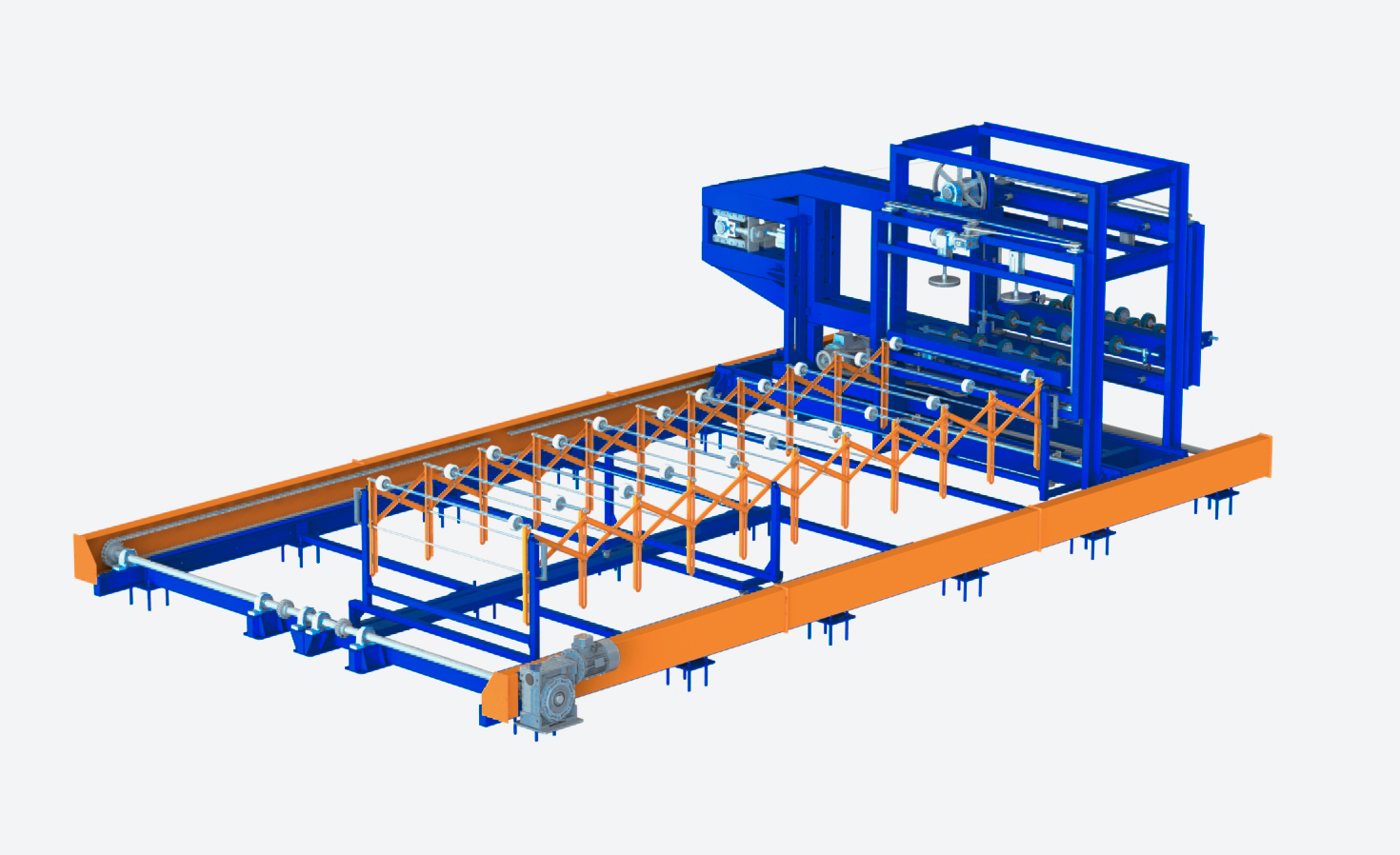

PR. 9 Caterpillar type press / iM-Press 9020 (9 m)

Caterpillar type press / iM-Press 9020 is designed to operate as part of a sandwich panel continuous laminating production lines and is used for uniform compression of the sandwich panel blank produced in a continuous production cycle.The tracked press unit comprises a superimposed upper and lower frame structure, designed for uniform compression of the sandwich […]

Specification

- Length, mm: 9830 (опционально от 6830 до 24830)

- Width, mm.: 2580

- Height, mm.: 2080

- Weight, kg.: до 28 000 (в зависимости от длины)

- Working field, мм: 1250 х 9000 (опционально от 6000 до 24000)

- Speed of operation, м/мин: до 6

- Developing pressure, кПа: 20

- Heating range, °С: до 40

- Panel manufacturing thickness, мм: 50…300

- Mains voltage, V - Hz : 220/380В-50Гц

- Power consumption, kW: 39

View other modules and sections of sandwich panel continuous laminating production lines

Sandwich panel production lines

«Basic»

Provides the possibility of further modernization and guaranteed quality of output product

Warranty service for 12 months from the date of launching the line.

Installation and commissioning

Post-warranty service and technical support

Post-warranty service and technical support