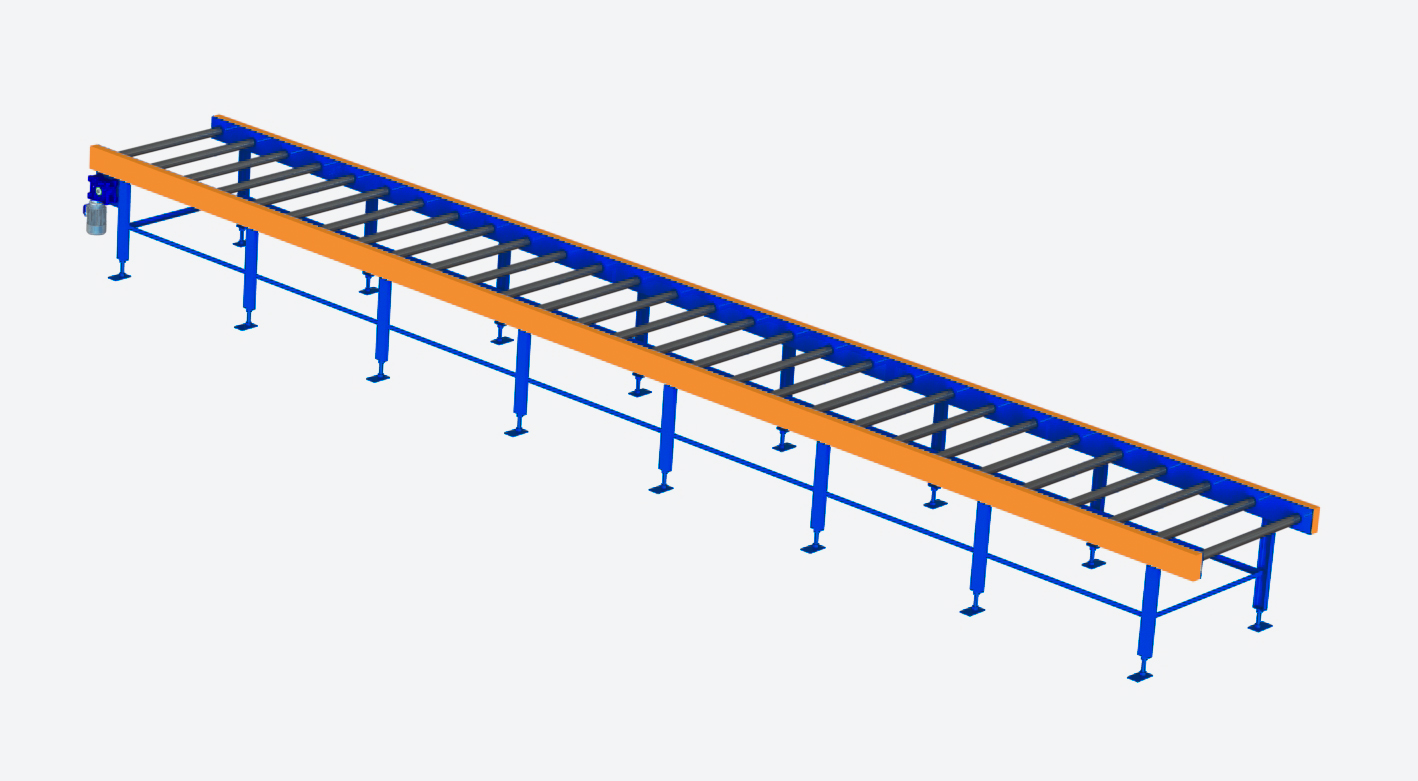

KL.4.1 Thickness calibration module

Thickness calibration module is designed to calibrate the thickness of a mineral wool board. Mineral wool thickness pre-calibration allows the production of mineral wool boards with the same geometric dimensions, which in turn reduces the load on the cutters of the disc cutoff block.

Specification

- Length, mm: 1650

- Width, mm.: 1920

- Height, mm.: 1580

- Weight, kg.: 780

- Mains voltage, V - Hz : 220/380В-50Гц

- Power consumption, kW: 3

View other modules and sections of sandwich panel continuous laminating production lines

Sandwich panel production lines

«Basic»

Provides the possibility of further modernization and guaranteed quality of output product

Warranty service for 12 months from the date of launching the line.

Installation and commissioning

Post-warranty service and technical support

Post-warranty service and technical support